Fully electric TAHARA blow molding machines. Stable process, high quality and precise final product.

In 1994, TAHARA was the first company in the world to successfully develop a fully electric blow molding machine.

Knowledge and experience, as well as data collected over the years, allow us to achieve high quality, production efficiency and reliability of machines.

files to download

01

TAHARA die head

All die heads are manufactured and assembled in-house at TAHARA’s factory in Japan, using the latest machinery and a highly skilled workforce. This ensures high quality and precise craftsmanship. For the design of internal flow channels within the die head, TAHARA uses proprietary software that incorporates flow analysis data, machine specifications, and production conditions — all with the goal of achieving the highest quality blown film. These strict standards and design methods are also applied to multilayer die heads.

design based on simulation

During machine design, TAHARA utilizes three main types of analysis:

- Flow analysis to design the appropriate die head and screw

- Structural analysis to identify areas where machine weight can be reduced while maintaining sufficient rigidity

- Cooling performance analysis to shorten cycle time

machine control system

TAHARA designs its machines based on two main principles:

- The machine must be capable of continuous, high-speed forming while maintaining process stability.

- The machine’s construction must be user-friendly.

As standard, the machines are equipped with a constant cycle forming system that ensures stable product molding. Additionally, the operating panel is a touchscreen, making the machine convenient and easy for the operator to use.

JSW group

![]()

In 2006, TAHARA became part of the JSW Group.

This integration enabled the exchange of knowledge and expertise between JSW — a supplier of machinery for the production of large-scale containers — and TAHARA, which specializes in equipment for manufacturing smaller containers.

Through their collaboration, the companies continue to enhance their technologies and drive innovation in blow molding.

02

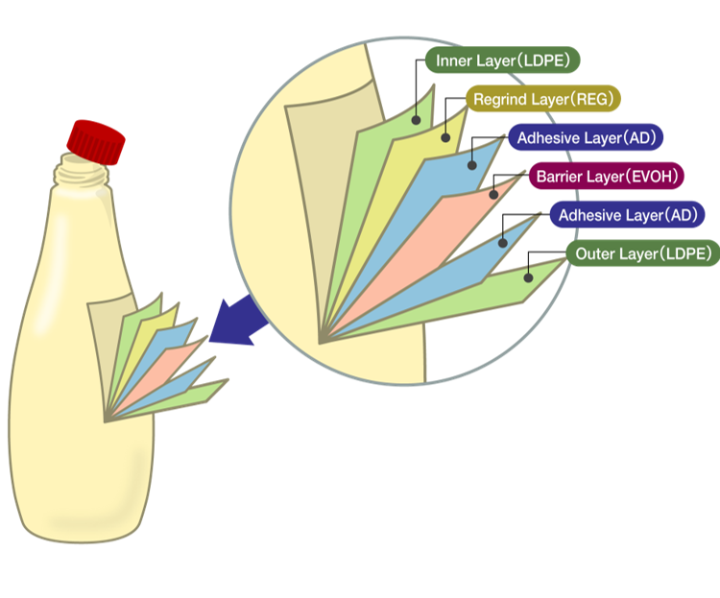

co-ex technology – multilayer die hard

TAHARA can provide machines equipped with die heads capable of producing up to 6-layer products. All die heads are manufactured and assembled in-house at TAHARA’s factory in Japan. Design solutions based on the company’s extensive experience, along with the high quality of components, ensure stable wall thickness even in multilayer configurations.

Using a multilayer die head allows for the incorporation of recycled material as the internal filler layer, which is both environmentally friendly and reduces production costs. A barrier layer provides protection against oxidation and chemical resistance. It is also possible to create a glossy outer layer, significantly enhancing the product’s appearance.

prevention mechanism of the mold parting line

By installing a synchronization mechanism on both the front and rear plates, the mold parting line deviation is maintained below 50 μm. This significantly improves the precision of the neck finish and extends the service life of calibration tools.

equalization mechanism for the calibration force

Even if the height of each blow core differs by up to 2 mm, this variation is automatically corrected by the calibration force equalization mechanism.

03

profitability

TAHARA blow molding machines offer a reduction in energy consumption of 40–60% compared to hydraulic machines.

A standout advantage is their low maintenance requirements. Unlike hydraulic systems, TAHARA blow molders do not require regular servicing such as oil changes or seal replacements, significantly reducing maintenance costs.

Additional factors that enhance the profitability of TAHARA machines include:

- increased productivity through shorter cycle times

- improved product quality

outstanding stability, precision, and performance

TAHARA machines feature a robust structure and proven electric drive technology.

Equipped with servo motors, they ensure precise positioning and movement speed, enabling the consistent production of high-quality products.

A fixed cycle molding system maintains a consistent parison length in each cycle, resulting in minimal variation in wall thickness and product weight.

clean operation

Thanks to their fully electric design (with no hydraulic system), TAHARA blow molding machines offer a cleaner and quieter production environment compared to hydraulic alternatives.

To schedule a consultation with our representative, please contact us.

Marcin Kasprowicz

+48 601 301 809

marcin.kasprowicz@wadim.com.pl